Supply Chain Disruption Reactions

Supply chain constraints remain a topical subject, as seen by the number of published press articles and the ever-increasing unreliability of many suppliers experienced by my clients and others.

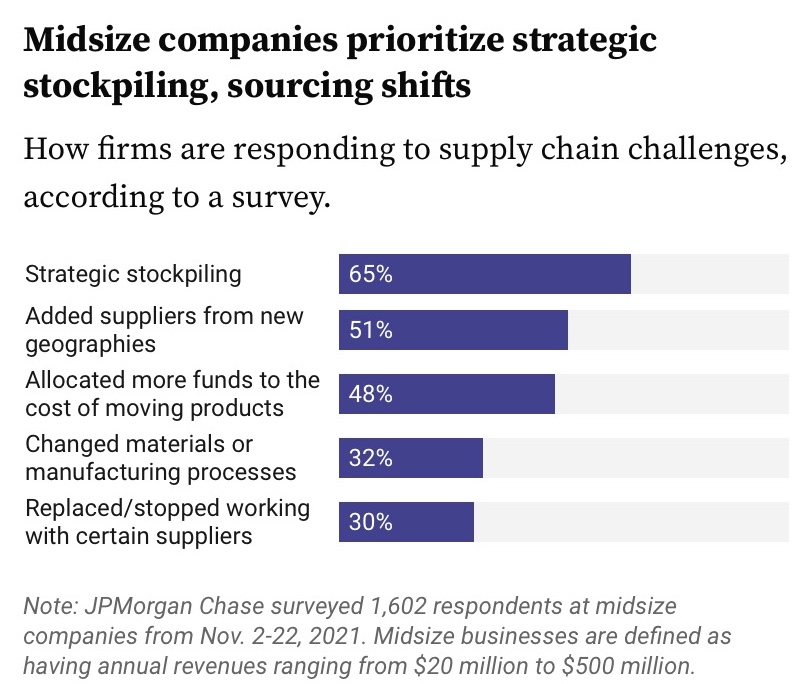

A study was recently undertaken by JPMorgan Chase on this topic, asking what actions had been taken to manage this level of disruption, and it highlighted some interesting reactions.

As you can see from the graphic below, the majority, 65%, bought and held more inventory. That is a natural reaction to a shortage and helps in the short term if and when that inventory is delivered. This has been the first step taken by most organisations.

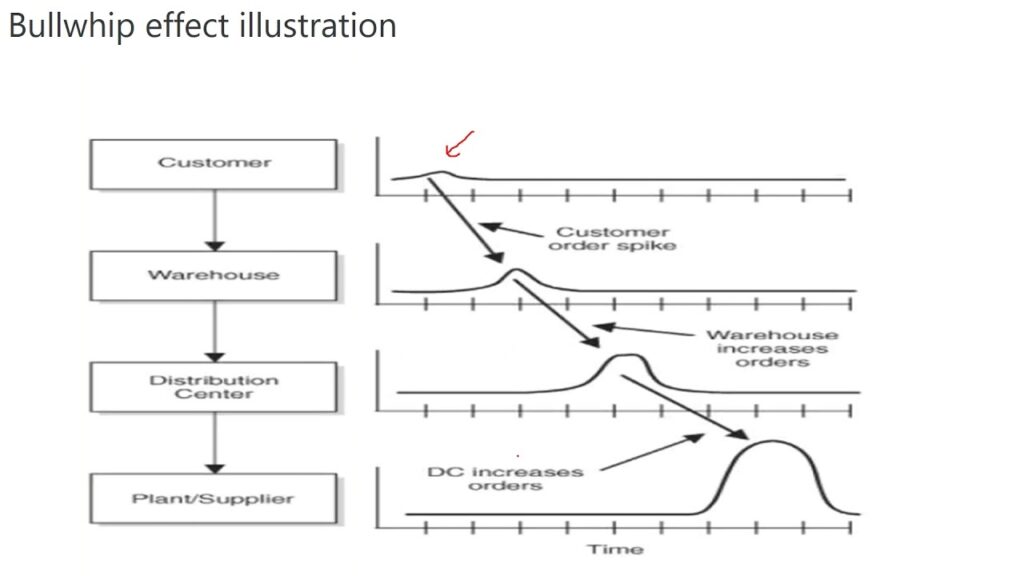

It does, however, add to the bullwhip effect (shown in the image below), which I have written about in previous newsletters. It actually makes the situation worse when others are doing the same thing thereby amplifying the issues the further away from the customer you are.

After resolving the initial shortages with extra inventory, it is pleasing to see many took subsequent actions that were more strategic. Activities include finding new suppliers and changing materials or manufacturing processes to find alternatives. Of course, finding new suppliers isn’t as easy in practice as it is to say. It involves time and effort to identify suitable alternatives, having negotiations with them, and testing their capability and quality before making the decision to shift some or all of your product to them.

What I find interesting is there is no mention of internal process improvement. What I feel is missing from this list, at least in the results of this survey, is:

- Improved S&OP processes – little mention is made about the adoption or improvement of S&OP processes.

- Improved sharing and visibility of demand with suppliers, it simply mentions changing suppliers. One viable alternative is to leverage different plants from the same supplier (where your supplier base has this capability), thereby de-risking your supply while maintaining your purchasing power. A common refrain against supplier diversification is loss of purchasing power and increased pricing.

- A focused effort of measuring supplier performance.

These are all steps you should be taking now to help you manage the disruption and current inflationary times.

bullwhip effect, inflation, inventory, supply chain disruption, supply chain management, supply chain resilience